Vitodens 222F B2TA 3.2 to 35 kW

Vitodens 222F B2TA 3.2 to 35 kW

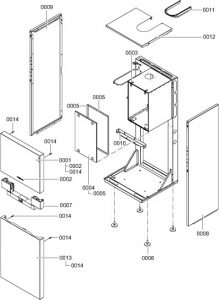

| ID | Parts Number | Part Description | Notes | Purchase |

|---|---|---|---|---|

| 1 | Front panel, top | |||

| 2 | Logo | |||

| 3 | Toggle fastener (4 pce) | |||

| 4 | Cover panel with profiled seal | |||

| 5 | Profiled seal | |||

| 6 | Adjustable foot | |||

| 7 | Control unit support | |||

| 8 | Side panel, right | |||

| 9 | Side panel, left | |||

| 10 | Loading cylinder mounting bracket | |||

| 11 | Top panel insert | |||

| 12 | Top panel | |||

| 13 | Front panel, bottom | |||

| 14 | Fixings for location stud (2 pce) | |||

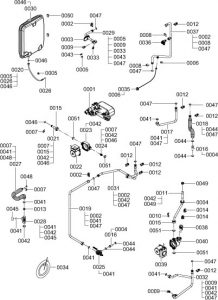

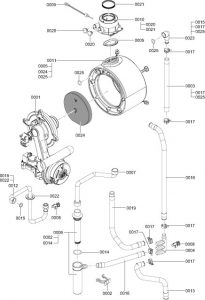

| 1 | Hydraulic block | |||

| 2 | Set of plug-in connector retainers (2 pce) | |||

| 3 | Diaphragm grommet (5 pce) | |||

| 4 | Diaphragm grommet (5 pce) | |||

| 5 | Clip Ø 8 (5 pce) | |||

| 6 | Clip Ø 10 (5 pce) | |||

| 7 | Clip Ø 15 (5 pce) | |||

| 8 | Clip Ø 18 (5 pce) | |||

| 9 | Air vent valve G3/8 | |||

| 10 | Spring clip (5 pce) | |||

| 11 | Connection pipe HR | |||

| 12 | Pipe clip Ø 18 / 1.5 | |||

| 13 | Fascia ? 13-19 kW Ø 4.0 (white) ? 26 kW Ø 5.5 (dark grey) ? 35 kW Ø 6.0 (beige) | |||

| 14 | Pipe clip Ø 18 | |||

| 15 | Union nut G1 | |||

| 16 | Sleeve | |||

| 17 | Connection pipe, heating water flow | |||

| 18 | Connection pipe, DHW | |||

| 19 | Connection pipe, cold water, cylinder | |||

| 20 | Expansion vessel connection line G 3/8 | |||

| 21 | Cold water hydraulic connection | |||

| 22 | Pump motor | |||

| 23 | CIL casing | |||

| 24 | Cartridge non-return valve | |||

| 25 | Shut-off valve, cold water, cylinder | |||

| 26 | Circular seal washer 8 x 2 (5 pce) | |||

| 27 | Connection line, DHW charging | |||

| 28 | Shut-off valve, DHW, cylinder | |||

| 29 | Flow pipe | |||

| 30 | Expansion vessel | |||

| 31 | Connection pipe, cold water | |||

| 32 | Connection pipework, heating water return | |||

| 33 | Thermal circuit breaker | |||

| 34 | Hose 10 x 1.5 x 1500 | |||

| 35 | Pressure gauge | |||

| 36 | Safety valve | |||

| 37 | Connection pipe, heating water flow, heat cell | |||

| 38 | Air vent valve | |||

| 39 | Circulation pump motor | |||

| 40 | CIAO casing | |||

| 41 | Gasket A 17 x 24 x 2 (5 pce) | |||

| 42 | Gasket 23 x 30 x 2, green (5 pce) | |||

| 43 | Temperature sensor | |||

| 44 | Gasket A 16 x 24 x 2 (5 pce) | |||

| 45 | Cap G 3/4 SW 30 | |||

| 46 | Gasket A 10 x 15 x 1.5 (5 pce) | |||

| 47 | O-ring 17.86 x 2.62 (5 pce) | |||

| 48 | O-ring 14.3 x 2.4 | |||

| 49 | Spring clip DN 25 (5 pce) | |||

| 50 | Plug | |||

| 51 | Gasket A 23 x 30 x 2, orange (5 pce) | |||

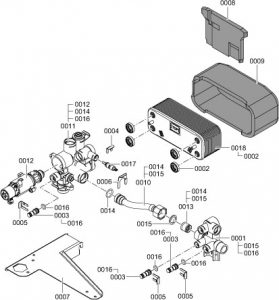

| 1 | Return unit | |||

| 2 | Profiled gasket | |||

| 3 | Plug Ø 8/Ø 10 | |||

| 4 | Clip Ø 8 (5 pce) | |||

| 5 | Clip Ø 10 (5 pce) | |||

| 6 | Clip Ø 18 (5 pce) | |||

| 7 | Hydraulic retaining bracket | |||

| 8 | Plate heat exchanger insulation board | |||

| 9 | Plate heat exchanger insulation shell | |||

| 10 | Overflow line | |||

| 11 | Flow unit | |||

| 12 | Valve insert | |||

| 13 | Overflow valve | |||

| 14 | O-ring 17.86 x 2.62 (5 pce) | |||

| 15 | Gasket A 17 x 24 x 2 (5 pce) | |||

| 16 | O-ring 9.6 x 2.4 (5 pce) | |||

| 17 | Temperature sensor | |||

| 18 | Plate heat exchanger | |||

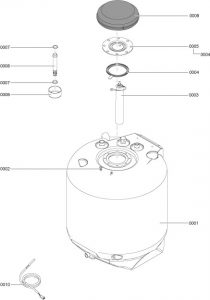

| 1 | Loading cylinder | |||

| 2 | Strain relief | |||

| 3 | Magnesium anode | |||

| 4 | Gasket | |||

| 5 | Flange with gasket | |||

| 6 | Cover | |||

| 7 | Gasket 23 x 30 x 2 (5 pce) | |||

| 8 | Sleeve | |||

| 9 | Flange insulation | |||

| 10 | Cylinder temperature sensor NTC 10k? | |||

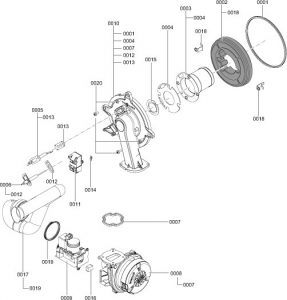

| 1 | MatriX cylinder burner | |||

| 2 | Spring clip, condensate drain | |||

| 3 | Profile hose, heating return | |||

| 4 | Condensate collector | |||

| 5 | Flue gasket | |||

| 6 | Siphon | |||

| 7 | Condensate hose | |||

| 8 | Pipe clip Ø 18 / 1.5 | |||

| 9 | Flue gas temperature sensor | |||

| 10 | Boiler flue connection | |||

| 11 | Heat exchanger | |||

| 12 | Gas pipe | |||

| 13 | Condensate hose | |||

| 14 | O-rings 35.4 x 3.59 (5 pce) | |||

| 15 | Gasket A 17 x 24 x 2 (5 pce) | |||

| 16 | Hose 19 x 600, corrugated | |||

| 17 | Spring clip DN 25 (5 pce) | |||

| 18 | Hose 19 x 270, corrugated | |||

| 19 | Hose 19 x 500, corrugated | |||

| 20 | Plug for boiler flue connection | |||

| 21 | Gasket DN 60 | |||

| 22 | Diaphragm grommet (5 pce) | |||

| 23 | Connection elbow, heating water return | |||

| 24 | Thermal insulation block | |||

| 25 | O-ring 63 x 2.62 (5 pce) | |||

| 1 | Burner gasket (wearing part) | |||

| 2 | Thermal insulation ring | |||

| 3 | Cylinder, burner gauze assembly | |||

| 4 | Gasket, burner gauze assembly | |||

| 5 | Ignition electrode (wearing part) | |||

| 6 | Ionisation electrode (wearing part) | |||

| 7 | Gasket, burner door flange (wearing part) | |||

| 8 | Radial fan | |||

| 9 | Gas train | |||

| 10 | Burner door | |||

| 11 | Ignition unit | |||

| 12 | Gasket, ionisation electrode (5 pce) | |||

| 13 | Gasket, ignition electrode (5 pce) | |||

| 14 | Blade terminal (10 pce) | |||

| 15 | Mixture restrictor | |||

| 16 | Gas nozzle ? 13 kW/19 kW: 02 yellow ? 26 kW: 04 grey ? 35 kW: 06 black | |||

| 17 | Venturi extension | |||

| 18 | Mounting plate, thermal insulation ring (2 pce) | |||

| 19 | Gasket DN 65 | |||

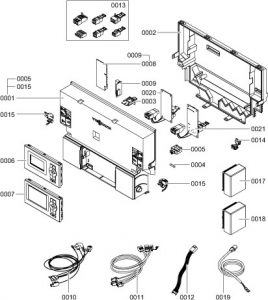

| 1 | Control unit | |||

| 2 | Control unit casing back panel | |||

| 3 | Coding card | |||

| 4 | Fuse 6.3 A (slow) (10 pce) | |||

| 5 | Fuse holder | |||

| 6 | Programming unit for constant temperature mode | |||

| 7 | Programming unit for weather-compensated mode | |||

| 8 | LON communication module | |||

| 9 | PCB adaptor | |||

| 10 | Cable harness X8/X9/ionisation | |||

| 11 | Cable harness 100/35/54/PE | |||

| 12 | Power cable, stepper motor | |||

| 13 | Mating plug (set) | |||

| 14 | Cable fixing | |||

| 15 | Locking bolts, left and right | |||

| 17 | Wireless outside temperature sensor | |||

| 18 | Outside temperature sensor (hardwired) | |||

| 19 | KM BUS connecting cable 145 | |||

| 20 | Internal H1 extension | |||

| 21 | Internal H2 extension | |||

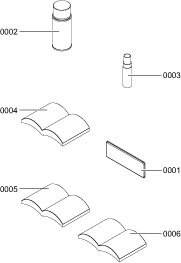

| 1 | Special grease | |||

| 2 | Touch-up spray paint, white | |||

| 3 | Touch-up paint stick, white | |||

| 4 | Installation and service instructions | |||

| 5 | Operating instructions for constant temperature mode | |||

| 6 | Operating instructions for weather-compensated mode |